“Azovelectrostal” history dates back to 1981 when the steel melting complex was put into operation at “Zhdanovtyazhmash”. This complex was intended for the production of casting products including armor steel.

At the beginning only one 25-ton furnace was operated, later the second furnace ДСП-25 was put into operation. V.I. Astakhov was the first chief of the workshop. At the end of 90s the operation of the steel making shop was practically stopped. The production facilities were vandalized. In July 1998 on its base Donetsk firm created “Radon Electrostal”, but practically it did not work. In December 2000 the enterprise was registered as CJSC “Azovelectrostal”.

The President of “Azovmash” A.V. Savchuk raised a question on restoration of the steel complex. Upon his initiative two furnaces ДВП-5 were constructed under the drawings of GSKTI designers. Later these furnaces were modernized up to volume capacities of 10 ton, and besides two furnaces ДСП-25 were restored. During a few years the degasser furnace was installed on the base of Sweden firm “ACEA”. In 2004 the first molding line of "Kunkel-Wagner" firm (Germany) was mounted. The designers of “Azovmash” took part in its engineering. Then the second molding line was erected for production of large car castings (KB-2) ensuring the own production of the side frames and top spring beams. Two ladle furnaces were installed. Despite the crisis of 2008 the construction of the furnace ДСП-60 (capacity of 60 ton) was finished and then the billet continuous casting machine for production of the billets of round sections with diameter of 400mm and 250mm was mounted.

In 2012 the new third line of "Kunkel-Wagner" for production of the medium and small car castings and two furnaces ДВП-5 were installed. The modernization of the continuous casting machine owing to the availability of the third strand permits to produce the billets of 125, 130 and 150mm.

All the equipment installed at “Azovelectrostal” recently including the fume-cleaning plant has been designed by the Italian firm “STG GROUP”.

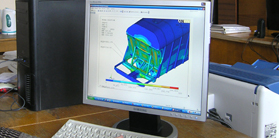

At present time Private Joint Stock Company “Azovelectrostal” (this name was assigned to the enterprise in 2011) includes the steel making production alongside with the scientific and technical complex uniting all the design engineering and technological departments.

The near-term plans of PrJSC “Azovelectrostal” include installation of the gas cleaning plant on the furnace ДСП-25 at the earliest possible time and preparation of the gas cleaning plant for the furnace ДВП.

At present owing to making of 550 ton liquid steel per year “Azovelectrostal” is able to manufacture car side frames, top spring beams, yokes, couplers, journal boxes and series of other castings, freight bogies, draft gears, etc.

Yuriy Dmitriyevich Serdyuk has been its General Director from 2011.