2013 became the banner year for the converter production at PJSC “Azovmash”. About 12 thousand ton of the main ranges of products were manufactured at PJSC “Azovmash, the great part of them are the converter products. Such result has been achieved for the first time for the last five years in spite of the continuing economic crisis. In total 7 converters were manufactured for the enterprises of “Metalinvest” (Ukraine), “Severstal” (Russia), Steel melting plant, Bokaro (India) and others in 2013.

At the present time PJSC “Azovmash” finishes manufacturing the body and the trunnion ring of 300 ton converter produced upon the Indian metallurgists’ order. Last month the trunnion ring of 160 ton converter was delivered to the metallurgists of the Yenakiyevo metallurgical complex. Now the manufacturing of another trunnion ring is completed. The production of the body components and trunnion ring of the converter is completed for the “Severstal” (Cherepovets, RF) as well.

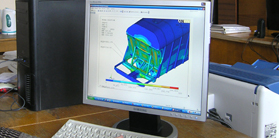

The design engineering department of the metallurgical equipment together with marketing specialists takes an active part in the pre-contract work. The engineering support of the design engineering department of the metallurgical equipment (KOMO) and scientific – technical complex (NTC) of PrJSC “Azovelektrostal” have ensured timely and exact execution of the assigned tasks.

“2013 was the successful year for the heavy machine building. Monthly the thousands ton of the equipment is produced, - Igor Nikolayevich Karapeychik, the General Director of PJSC “Azovmash” noted. - The most part of the heavy machine building products is manufactured for the metallurgists of Ukraine, Russia, and far abroad countries. The successes of industry have been achieved owing to the improvement of the produced equipment design, the methodical work of the production facilities.